Case Studies

On-Site Recycling Management

In 1994, a Fortune 500 company based in Upstate New York decided to outsource their metal recycling function. After reviewing the financial performance of their existing program, as well as the apparent incompatibility with its core competencies, they invited nearly fifty companies to respond to an RFP. Integrated Recycling Services Company worked through the process and ultimately entered a ten-year contract to manage the on-site metal recycling operation.

After just one year, IRSC turned the bottom line results of this department from a loss of nearly $500,000 to a profit of over $1,000,000. In addition, Integrated enhanced the operation by promoting and maintaining its mission of: open door/open book, top health, safety and environmental standards, enhanced revenue through direct sales to consumers with reduced expenses through effective operations practices, and material “watchdog” services ensuring that no useable goods were errantly disposed and thus properly redeployed.

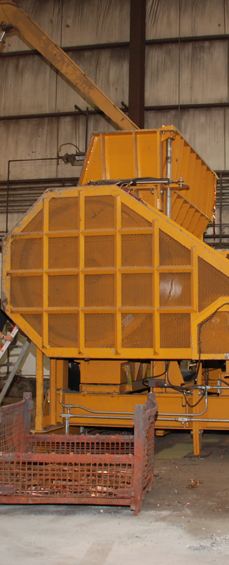

The emphasis has been to receive, sort, process and effectively market all metallic surplus and scrap from throughout the client's campus. In addition, our services include continued interface and consultation with our customers, the generating buildings and departments within the site. An on-site manager responds daily to inquiries and helps promote the most efficient and cost effective means of handling, transportation and final disposition, while maintaining the highest environmental standards.

Using its core business model of “bundling” all recycling functions, IRSC hopes to expand the scope of services with this client to include paper, plastics, electronics, general waste and useable equipment.

Out-Sourced Recycling Management

After a very competitive RFP and RFQ process, Integrated was awarded its first contract with another Fortune 500 company, based in Upstate New York, in April, 1997. As with our other customers, they recognized the need to outsource the surplus and scrap metal recycling function and turned to IRSC. Since then, the original agreement has been extended and expanded to include electronics, plastics and on-site coordination of all material disposition.

The results for this relationship speak for themselves. After successfully creating a profit center for most of the recyclable goods generated through manufacturing or disassembly, IRSC has been invited to participate in an RFQ for yet further streams of recyclables including: paper, all plastics, electronics, general waste and hazardous waste. Integrated expects to deploy its vast network of resources (third party vendors, second tier suppliers) to provide service and equipment in all areas to enhance the value for and relationship with our client.